Waterproof Product Development

by Sanwa Shutter Corporation

We introduce our technology behind "Waterproof Products"

and the thoughts put into them.

In recent years, large typhoons and torrential downpours have caused flooding and submergence damage one after another. In order to protect companies, facilities, and people's lives from urban flooding that can occur at any time, it is important to stay prepared. Sanwa Shutter Corporation has released many waterproof products since 2014, providing products and services that contribute to safe, resilient, and sustainable cities.

We interviewed Mr. Tsuji of the Product Development Department to learn more about the technologies enabling these waterproof products and our sincere wishes carried by them.

Chapter01

Why focus on waterproof products?

Development started in the wake of the Great East Japan Earthquake

The development of waterproof products at Sanwa Shutter Corporation was triggered by the Great East Japan Earthquake of 2011. At that time, severe flooding damages caused by tsunami in the coastal areas of the affected region highlighted the need for shutters with waterproof functions to cope with natural disasters. Since then, to protect the lives and valuable assets of our customers as a leading manufacturer of shutters and doors, we have been working on relevant product development and have sincerely responded to our customers' voices until today.

For example, a customer operating a sewerage facility who experienced damage by tsunami asked us to develop a door "easier to operate than conventional products and reliably waterproof". We began by surveying those buildings within the facility that had suffered less flood damage to learn how we could prevent flooding. We checked various aspects, including the fit of the door, frame shape, door structure, and the angle at which the tsunami hit the building, and reflected these in the new product development. These efforts gave birth to the "Water Guard W Tight Door".

During the same time, we were also working on the development of a waterproof shutter and released "Water Guard W Tight Door". in 2014. When we delivered our first waterproof shutter, not only the installation department but also everyone involved in the product including development, design, and sales teams attended the site. I remember that several areas have changed from the prototype stage by that time, hence the installation took longer time than expected. Compared to those early days, the performance of our products and installation techniques are far more advanced today and we now have very mature products.

Chapter02

What disaster prevention products does Sanwa offer?

Extensive product lineup

to meet diverse waterproofing needs

Currently, we offer three categories of waterproofing products: shutters, doors, and waterproof panels. Both shutters and doors are available in two types. Among them, the "Fire-and-smoke-proof Type Water Guard Waterproof Shutter" has been highly evaluated as the industry's first product for protection against not only water damage but also fires. It also won the "Grand Prize (new product development category) of the Disaster and Epidemic Prevention Product Award" in 2021.

As for waterproof panels, we offer a lineup of about 20 different types with different materials and installation methods. The standard type of waterproof panels are kept in storage rooms and taken out for installation when needed. But there are also other types including those stored under the floor which can be quickly pulled out and set in place when necessary, and those automatically raise or lower the floor height. We also sell a variety of lightweight products made of aluminum, resin, and other lighter materials.

Taking on the challenge of developing products

to withstand greater disasters with less effort

Ensuring our waterproof products can be shut "quickly, safely, and reliably" to minimize flooding damage has been the objective of our development. When disaster strikes, we can't afford dozens of minutes for waterproofing setup of every single door - the damage will quickly spread in that case. Therefore, we develop and design our products to meet the standard of "waterproofing operation completed within 5 minutes".

In particular, our single swing waterproof doors are equipped with a self-closing device, so they can withstand floodings up to 1-2 meters once you remove your hand from the door and it automatically closes. This means that the waterproofing operation can be completed by simply leaving the door to close.

How much flooding must a product be designed to withstand? The expected performance for such product type has been rising year by year. 10 years ago, the prevailing logic of thinking was "we had flooding up to this height in the past, so let's make sure we can handle it". However, with severe disasters that used to be described as "once every 50" or "once every 100 years" now occurring every year, people have become increasingly concerned that a disaster greater than expected may strike even tomorrow. Accordingly, we are required to deal with increasingly higher flooding levels rather than what is specified on the Hazard Maps. Therefore, we have been working on enhancing the waterproof capability of each of our current products in recent years, so they can withstand higher flooding levels.

The development of waterproof products requires technologies to eliminate gaps and prevent water from leaking through the overlapping members as they expand under water pressure. Therefore, we needed to adopt a different way of thinking as compared to the development of conventional shutters and doors.

To build a waterproof shutter, waterproof rubber is placed above and below each movable panel and on the guide rail on the fixed side, and a power cylinder is used to compress the panels both vertically and horizontally to achieve the water-sealing function. As I recall, we struggled to stop the water at contact points between the movable and fixed components.

Another challenge was to overcome the deflection of the shutter when pushed by the pressure of water which would create gaps. The wider the shutter opening and the higher the designed water level, the higher the technical barrier we had to break through.

Upon each and every new product development or specification change, the development team members conduct various tests dozens of times to check leakage points and review the deformation structure of each material through repeated trial and error.

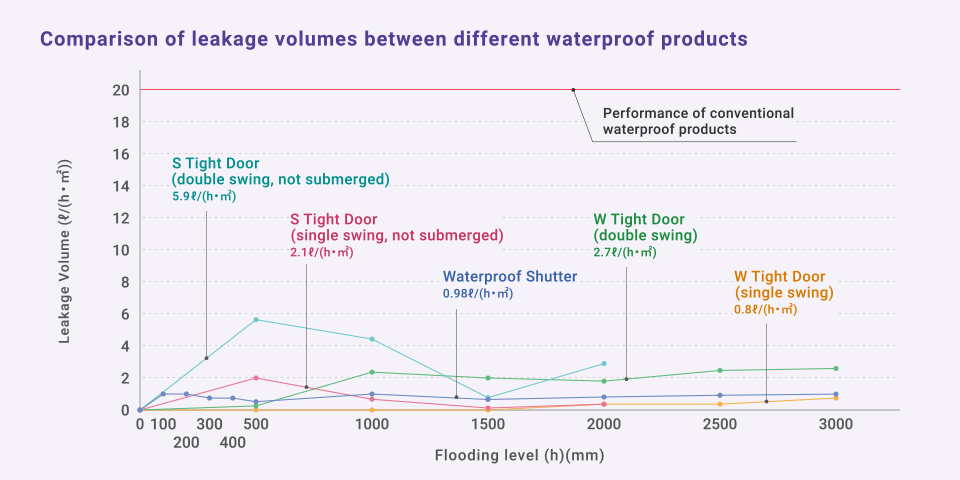

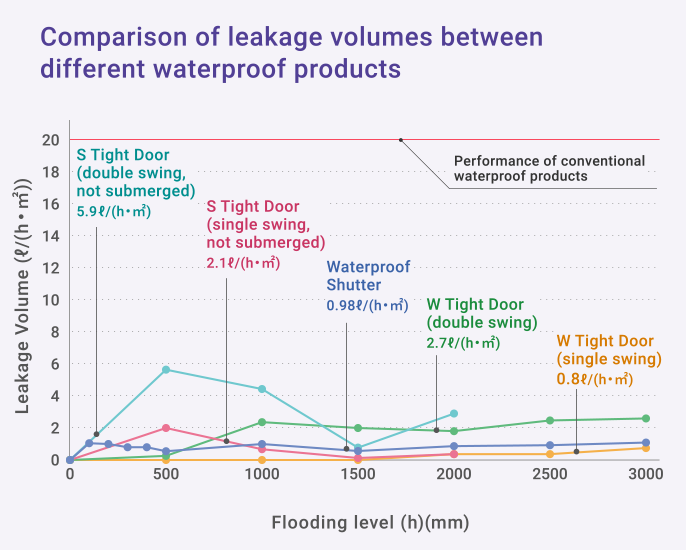

A comparison of the leakage volume between our products shows more leakage when the flooding height is lower, such as in the case of the "S Tight Doors". This may seem counter-intuitive at first glance, but this is because our doors actually need the force of water to seal. The higher the flooding height and the stronger the force of water pushing against the door, the harder the door is pushed inward and sealed, resulting in less leakage.

The opinions of each department including the factory, quality, design, and sales teams are also important factors to consider during the development process. We believe that incorporating the opinions of a variety of people, not only waterproofing experts, would help create products that meet the needs of society. We also go visit the installers to learn what they are struggling with through casual conversations. This is because we place particular importance on meeting in person with product users and listening to their requests.

Chapter03

Sanwa's technological capabilities to create disaster prevention products

Superior technological capabilities enabling high-performance products

For waterproof shutters, it is essential not only to have superior waterproof function in the event of a disaster, but also to ensure durability, performance, and quality as a control shutter at all times. We only deliver products that have passed more than 10,000 times of repeated opening & closing tests. We have confidence in our products supplied to customers because they are manufactured and sold in Japan and meet the strict Japanese national standards (JIS).

The installation of waterproof products involves a number of precautions and attention to detail different from those for ordinary shutters and doors. For this reason, we have a licensing scheme for the installation of our waterproof shutters and doors. Through this system, we guarantee quality by ensuring that installation is performed only by technicians who have acquired competent skills at our installation training center.

In addition, for the very reason that the waterproofing function is not frequently used, regular maintenance is crucial to eliminate the chance of malfunctions in case of emergency. We recommend conducting inspections twice a year after the initial installation. We also clearly set replacement times for rubber and other components and compile them in documents to share with the maintenance and service departments.

As our direction going forward, we would like to utilize recycled and eco-friendly materials in our products, given the growing interest in environmentally friendly materials in today's world.

We will also continue to improve the quality and performance of our products, in order to cope with multi-hazards such as torrential rains, intense winds, and earthquakes. To help our customers to solve their problems, we will make sure our research and development will always stay one step ahead of them.