Initiatives Towards a Decarbonized Society

Policy

The Sanwa Group contributes to the realization of a sustainable, affluent society through the emission reduction of CO2 and other greenhouse gases in order to appropriately address climate change risks.

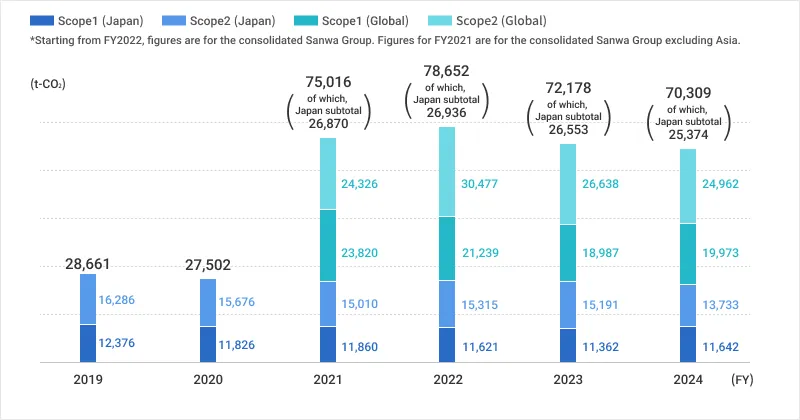

CO2 Emission Reduction Targets and Trends

The Sanwa Group recognizes the impact of our business operations on the global environment and the importance of mitigating this impact. In May 2022 we established new environmental targets and a new policy for achieving carbon neutrality. In addition, under the Medium-Term Management Plan 2027, we announced our CO2 emissions reduction target for fiscal year 2027.

CO2 Emission Reduction Targets

FY2027

20% reduction from FY2019 level

- Sanwa Shutter Corporation

FY2030

30% reduction from FY2019 level

- Sanwa Shutter Corporation

FY2050

Sanwa Group aims to achieve net zero CO2 emissions from business activities

CO2 Emission Reduction Trends (Japan, Global)

- In December 2022, Japan's figures from FY2019 to FY2021 updated following a change in calculation method in line with a third-party verification. Adjusted emission factors have been used since FY2019.

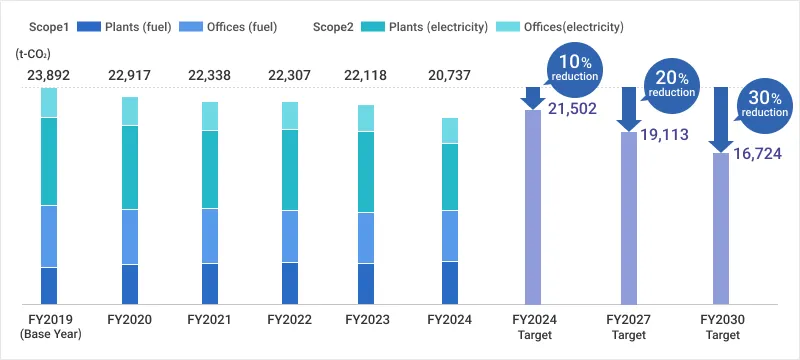

Initiatives to Reduce Energy Consumption and CO2 Emission

Sanwa Shutter Corporation and other domestic group companies in Japan have established and are operating an environmental management system based on ISO 14001 guidelines, and we are working to reduce our impact on climate change by setting targets for energy reduction and efficiency, as well as targets for lower CO2 emissions.

CO2 (Scope1+2) Emission Reduction Trends (Sanwa Shutter Corporation)

- Figures from FY2019 to FY2021 have been updated following a change in calculation method in line with a third-party verification. Adjusted emission factors have been used since FY2019.

- The Japan Management Association Sustainability Center (JMASusC) has provided third-party verification of the values for Sanwa Shutter Corporation's CO2 emissions from FY2021

- From the fiscal year 2023, it includes of heat and steam supply received by the Shinjuku Mitsui Building from the Shinjuku District Heating and Cooling Center.

To achieve our CO2 reduction targets, Sanwa Shutter Corporation calculates and reduces Scope 1 emissions (direct emissions from business activities) and Scope 2 emissions (indirect emissions from the manufacturing stage of energy used in business activities) at production sites (plants) and nonproduction sites (offices).

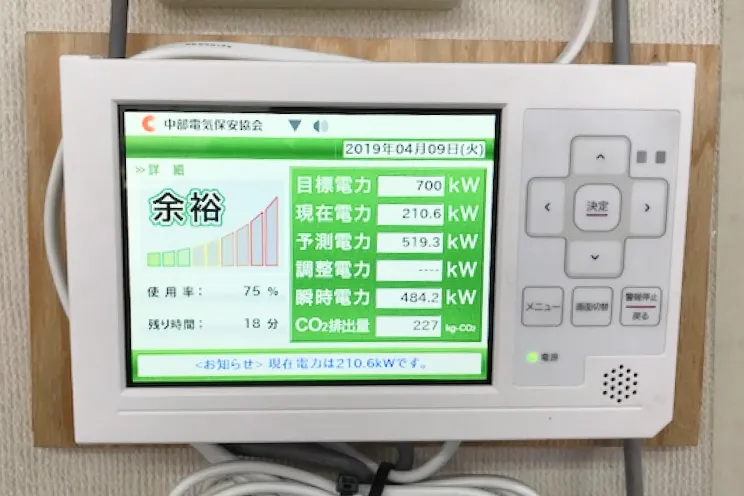

At our plants, initiatives for reducing Scope 1 emissions include upgrading to energy-efficient equipment and reducing operating hours by improving productivity. Scope 2 emission reductions include using renewable energy, switching to LED lighting, as well as using monitoring systems to visualize demand and consumption of electricity to reduce energy use.

In March 2021, Sanwa Shutter's Ota Door Plant switched from using boilers for drying paint to using electric fan heaters, reducing kerosene consumption by more than half.

We have also been promoting the installation of solar generation power systems. Solar panels were installed on the roof of the logistics building at the Ota Door Plant in December 2021, on the premises of the Kyushu Plant in July 2023, and on the roof of the Shizuoka Plant in September 2024. In April 2025, a solar carport was installed in the parking area of the Ota Door Plant. In our offices, in addition to switching to LED lighting and updating air conditioning systems, the company is also switching to eco-friendly sales vehicles to reduce gasoline consumption.

As a result of these initiatives, Sanwa Shutter Corporation's CO2 emissions (Scope 1 + 2) in FY2024 decreased by 13.2% compared to the base year of FY2019, achieving the FY2024 target of a 10% reduction from FY2019 levels (a 6.2% decrease compared to the previous year). Nationwide emissions also decreased by 4.4% compared to the previous year. We will continue to promote measures to achieve the FY2027 target of a 20% reduction from FY2019 levels, as announced in the Medium-Term Management Plan 2027.

(Ota Door Plant logistics building)

(Kyushu Plant)

![Graph of Changes in Facility Energy Efficiency [Factory]](/english/csr/assets/img/environment/img_contributive07-en_20251016.webp)

![Graph of Changes in Facility Energy Efficiency [Offices]](/english/csr/assets/img/environment/img_contributive08-en_20251016.webp)

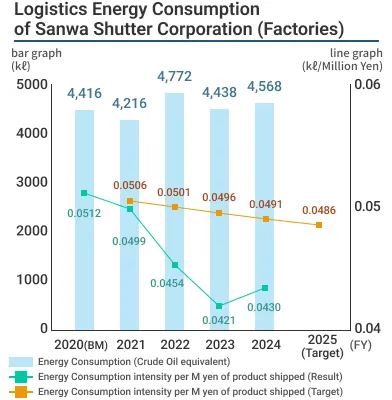

Initiatives to Reduce Energy Consumption in Logistics (Sanwa Shutter Corporation)

Adhering to the Law Concerning the Rational Use of Energy, Sanwa Shutter Corporation is working to achieve a 1% reduction in energy consumption intensity of production per year and a 1% average improvement in energy consumption intensity of production per year over five years. To reach these goals, the Company is implementing multiproduct mixed delivery using depots (small distribution centers) in the Tokyo metropolitan area, Sendai, and Shikoku. In addition, in July 2020, the Company introduced a vehicle dispatch and warehouse management system to improve the efficiency of vehicle dispatching and promoted better warehouse entry/exit and inventory management. These moves helped improve the loading ratio and reduced the number of vehicles sent out.

Initiatives to Reduce Energy Consumption and CO2 Emission (North America)

In FY 2021, ODC began calculating CO2 emissions (Scope 1 + 2) from ODC headquarters and all plants. The results for FY 2024 were 26,743t-CO2 (Scope1: 8,781 t-CO2, Scope2: 17,961 t-CO2), representing an approximately 5.4% increase from the previous year.

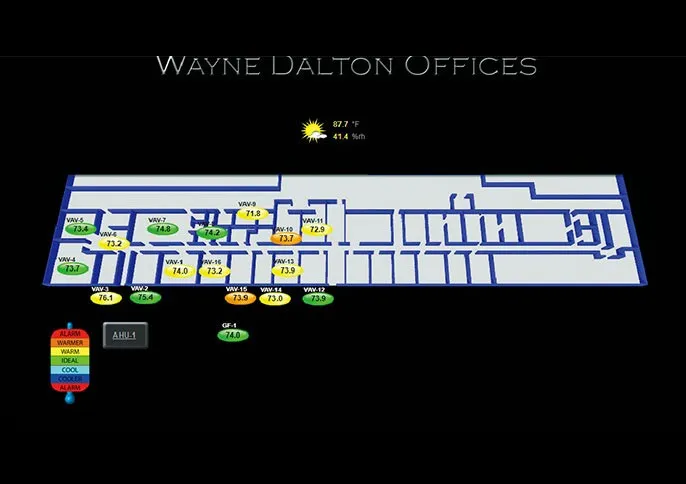

Pensacola plant of ODC uses computer-controlled lighting and an energy-efficient air-conditioning system in order to reduce unnecessary energy use.

Additionally, the Centralia plant has switched to energy-efficient lighting and Won-Door has not only changed the office area lighting to LED but also upgraded the HVAC systems to more energy-efficient models, striving to reduce energy consumption.

Initiatives to Reduce Energy Consumption and CO2 Emission (Europe)

In FY 2021, NF Group began calculating CO2 emissions (Scope 1 + 2) from NF GmbH headquarters and all plants. The results for FY 2024 were 16,425t-CO2 (Scope1: 10,806 t-CO2, Scope2: 5,619 t-CO2), representing an approximately 4.0% decrease from the previous year.

Within the NF Group, ISO 14001 certification has been obtained at the Riexinger plant in Germany, the NF Door plant in Poland, the RobustAB's plant in Sweden, and Vertriebs sales company in Germany. In addition to efforts to reduce energy consumption, the group is promoting the transition of company-owned vehicles in Germany and the UK to electric or plug-in hybrid models, as well as the purchase of electricity derived from renewable energy sources.

(Luton Plant)

(Schievano Plant)

Initiatives to Reduce Energy Consumption and CO2 Emission (Asia)

In FY 2022, Asian subsidiaries began calculating CO2 emissions (Scope 1 + 2) from Asian subsidiaries headquarters and all plants. The results FY 2024 were 1,767 t-CO2 (Scope1: 386 t-CO2, Scope2: 1,381t-CO2), representing an approximately 43.6% decrease from the previous year.

We have introduced solar power generation facilities at Shanghai Baochan-Sanwa Door since May 2023, contributing to the reduction of CO2 emissions and electricity costs. Additionally, solar power generation facilities were installed at Sanwa NF Changshu, and operations

commenced in June 2024. The total panel area is 6,680 m2, with an expected annual reduction of approximately 1,397 t of CO2 emissions.

(Shanghai Baochan-Sanwa Door)

(Sanwa NF Changshu)

Scope 3 Initiatives

To achieve a carbon neutral society, it is necessary to reduce CO2 emissions not only within the Company but also throughout the entire supply chain. For the first step to reduce overall CO2 emissions in the supply chain, we began calculating the previous year's results of Scope 3

emissions (Categories 1, 3, and 4) from the FY 2023. Starting in FY2024, calculations for Categories 2, 5, 6, 7, 10, and 11 were newly introduced. As a manufacturer, we have obtained third-party verification for Category 11 (use of sold products) = the CO2 emissions resulting from the use of products sold to customers, which is closely related to us.

Scope 3 Emission Calculation Results and Calculation Method

Fiscal year: FY2024(From 1/April/2024 to 31/March/2025)

Boundary: Sanwa Shutter Corporation

| IItem | CO2Emission (t-CO2) |

Calculation Method | Third-Party Verification |

|||

|---|---|---|---|---|---|---|

| Activity volume | Emission intensity ※ | |||||

| Scope3 | 434,575 | |||||

| Category 1 | Purchased goods and services | 272,650 | Purchased weight of steel, stainless steel, and aluminum |

Emission intensity per purchased weight | 〇 | |

| Category 2 | Capital goods | 9,175 | Capital expenditure | Emission intensity per price of capital goods | ― | |

| Category 3 | Fuel and energy related activities not included in Scope 1 or Scope 2 | 4,677 | Energy consumption for fuel and electricity |

Emission intensity per energy volume | 〇 | |

| Category 4 | Upstream transportation and distribution | 12,311 |

Fuel consumption (diesel) related to the transportation of goods (factories to sales offices) which Sanwa Shutter was identified as the consigner |

Emission intensity per weight of diesel | ― | |

| Category 5 | Waste generated in operations | 2,156 | Waste disposal cost | Emission intensity per waste disposal cost | ― | |

| Category 6 | Business travel | 429 | Number of employees | Emission intensity per number of employees | ― | |

| Category 7 | Employee commuting | 1,396 | Number of employees by work location |

Emission intensity per by work location and working day |

― | |

| Category 10 | Processing of sold products | 43,651 | Product installation outsourcing cost |

Emission intensity per product installation outsourcing cost | ― | |

| Category 11 | Use of sold products | 88,131 |

Lifetime electricity consumption of products that use the electricity sold in the target year |

Emission factors by electricity provider and alternative values |

〇 | |

- Uses emission coefficients indicated in "Database of emissions unit values for Greenhouse Gas Emissions Throughout the Supply Chain(ver.3.4)"and "National Institute of Advanced Industrial Science and Technology IDEA Ver.2.3".

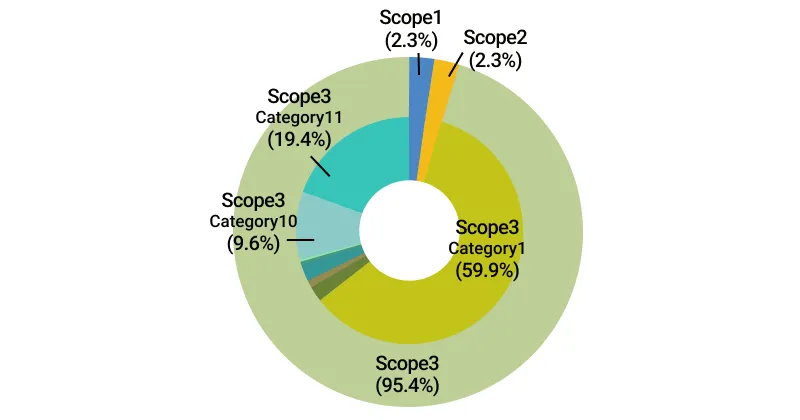

Scopes 1, 2, 3 Emissions and Composition

The total emissions for Scope 1, 2, and 3 in the FY 2024 amounted to 455,312 t-CO2. Scope 1 emissions were 10,400 t-CO2 (2.3% of the total), and Scope 2 emissions were 10,337 t-CO2 (2.3% of the total), while the total emissions for Scope 3 were 434,575 t-CO2, accounting for 95.4% of the total. Particularly, emissions from Scope 3 Category 1 were 272,650 t-CO2, representing 59.9% of the total, and emissions from Category 11 were 88,131 t-CO2, representing 19.4% of the total, constituting a significant portion.

Fiscal year: FY2024(From 1/April/2024 to 31/March/2025)

Boundary: Sanwa Shutter Corporation

| Item | CO2Emission (t-CO2) |

Breakdown (%) | Third-Party Verification |

|||

|---|---|---|---|---|---|---|

| Percentage of total | Percentage within Scope3 | |||||

| Scope1 | 10,400 | 2.3 | ― | 〇 | ||

| Scope2 | 10,337 | 2.3 | ― | 〇 | ||

| Scope3 | 434,575 | 95.4 | 100.0 | |||

| Category 1 | Purchased goods and services | 272,650 | 59.9 | 62.7 | 〇 | |

| Category 2 | Capital goods | 9,175 | 2.0 | 2.1 | ― | |

| Category 3 | Fuel and energy related activities not included in Scope 1 or Scope 2 | 4,677 | 1.0 | 1.1 | 〇 | |

| Category 4 | Upstream transportation and distribution | 12,311 | 2.7 | 2.8 | ― | |

| Category 5 | Waste generated in operations | 2,156 | 0.5 | 0.5 | ― | |

| Category 6 | Business travel | 429 | 0.1 | 0.1 | ― | |

| Category 7 | Employee commuting | 1,396 | 0.3 | 0.3 | ― | |

| Category 10 | Processing of sold products | 43,651 | 9.6 | 10.0 | ― | |

| Category 11 | Use of sold products | 88,131 | 19.4 | 20.3 | 〇 | |

- Numbers may not add up to 100% due to rounding.

Collaboration with external organizations

As a member of Keidanren (Japan Business Federation), the Sanwa Group exchanges information related to climate change. Moreover, the Representative Director Chairman of Sanwa Shutter Corporation, our Group company, has served as Chairman of the Japan Rolling Shutters & Doors Association (JSDA), and has been working hard on flood prevention. The goal is to create a resilient society that can withstand intensifying natural disasters due to climate change. We have also been actively involved in the management of this association, including the appointment of the Representative Director and Chairman of Sanwa Shutter Corporation as its chairman.

Sanwa Shutter Corporation complies with Japan's Law Concerning the Rational Use of Energy, a law that addresses climate change in Japan. As well, we submit reports to the government once a year on energy consumption, our achievement of energy conservation targets, and greenhouse gas emission volumes.