Policy

The Sanwa Group promotes efficient and sustainable use of water and raw materials and recycling initiatives in all business processes and throughout the product life cycle from procurement to disposal in an effort to reduce waste.

Basic Approach

As a global manufacturer of shutters, doors, and other such parts, the Sanwa Group uses many resources, including metals and energy. The Sanwa Group is contributing to the realization of a recycling-oriented society by improving energy efficiency in product design and the production process to effectively utilize resources. We are actively working to reduce waste by extending product life, conserving resources through reduction of the weight of products and the number of parts, designing products with consideration for recycling, and reusing waste. In addition, we consider the global social issues of water shortages and depletion as business risks, and work to conserve water resources by strengthening our management of water use in the production process and other business activities.

Environmentally Friendly Design (3R design)

Water Resources Conservation

Policy

Due to global climate change and the growing demand for water as a result of rapid population growth, the depletion of water resources and shortages are becoming serious issues for society. As the Sanwa Group is continually growing globally, we believe that the preservation and effective use of water resources is crucial. For this reason, we are taking the initiative to help preserve these resources. We are working to decrease the volume of water consumed at every production base by strengthening the management of water use, improving production processes, and reusing water. Further, we work to comply with all local laws and regulations on wastewater quality control.

Target

In May 2022, we set KPIs that are linked to our ESG material issues. For water resources, we set the following target for water usage intensity.

| Targets(KPI) | Target Year | Achievements and progress in fiscal 2022 |

Future challenges |

|---|---|---|---|

| Reduction of water usage intensity (at factories and offices): Reduce by 10% compared to FY2020 |

FY2030 | Reduce by 6.3% compared to FY2020 |

・Promotion of water conservation ・Facility upgrades |

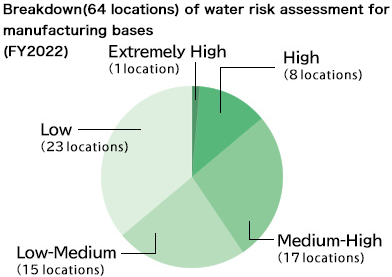

Water stress analysis

The Sanwa Group regards water shortages as a risk that could impact plant operations, and we have been using the Aqueduct Water Risk Atlas developed by the World Resources Institute. This online atlas helps us to evaluate water stress (the degree of urgency of water demand and supply) in the countries and regions worldwide where are production bases are located. The Sanwa Group operates 64 production bases, and of these we have discovered high water stress at 9 locations (14% of total): and have calculated that the total water intake volume is 24,048t.

Formulating the Sanwa Group’s water management plans

As of March 31, 2023, 6 of Sanwa Shutter Corporation’s 8 plants (75% of total), have formulated water management plans to make effective use of water resources and to reduce our environmental impact. For example, at Sanwa Shutter Corporation’s Ota Door Plant, we have introduced water circulation systems (for painting equipment and chillers) to save energy and improve the efficiency of water resources, and we have secured the required water volume through joint use of tap water, industrial water, and stored (tank) water. In addition, wastewater is purified in septic tanks, and we clear water quality standards by regularly conducting septic tank water quality inspections and wastewater treatment inspections.

Actions to reduce the volume of water consumption

At Sanwa Shutter Corporation’s plants, we are working to reduce water consumption and wastewater volume by using chilled tank water in water circulation systems (for painting equipment and chillers).

Moreover, for an example of working at individual bases, we introduced water-saving valves in 2018 at Sanwa Shutter Corporation’s head office building. In this way, we reduced the water volume by approximately 27% year on year.

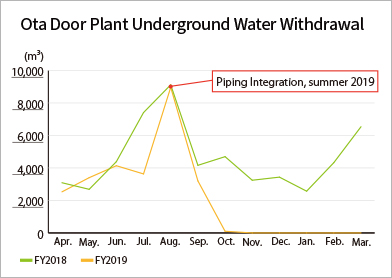

In FY2019 at Sanwa Shustter’s Ota Door Plant, we integrated piping to optimize circulating cooling equipment. This enabled cooled water from chillers onsite to be supplied to a cooling tower, where cooling capability had in the past been supplemented with underground water. As a result, the plant achieved a major reduction in the volume of underground water consumed.

(Underground water withdrawal: Second half of FY2018 24,804m3→ Second half of FY2019 103m3)

Cooling tower

Ota Door Plant Underground Water Withdrawal

Number of violations of laws and regulations relating to water intake and wastewater (discharge)

There were no cases of violations of laws and regulations relating to water intake and wastewater (discharge) in FY2022.

Waste Reduction

Policy

The Sanwa Group strives to promote recycling, minimize waste and reduce the environmental burden in all departments.

Target

In May 2022, we set KPIs that are linked to our ESG material issues. For waste reduction, we set the following target for waste intensity.

| Targets(KPI) | Target Year | Achievements and progress in fiscal 2022 |

Future challenges |

|---|---|---|---|

| Reduction of waste intensity (at factories and offices): Reduce by 10% compared to FY2020 |

FY2030 | Reduce by 26.1% compared to FY2020 |

・Further thorough sorting and recycling ・Facility upgrades |

Initiatives to Reduce Waste (Japan)

Sanwa Shutter Corporation strives to improve waste separation as a means to reduce waste from our plants and is taking steps to improve yield by reusing of wooden pallets used in transportation and changing the dimensions of parts and materials. In addition, at Ota Door Plant and Hiroshima Plant, our core door plants, paint adhesion rates have increased and the amount of waste coating has fallen significantly as a result of major improvements to our coating line.

In fiscal 2022, waste emissions were reduced by 10.5% from the previous year through more exhaustive sorting and recycling and by reusing wooden pallets at plants. Waste emissions intensity was also reduced by 26.1% compared with the base year of fiscal 2020, due in part to net sales growth.

| Item | FY2019 | FY2020 (Base Year) |

FY2021 | FY2022 | FY2023 (Target) |

|

|---|---|---|---|---|---|---|

| Waste Emissions (t) | 2,061 | 2,145 | 1,982 | 1,870 | - | |

| Waste Emissions intensity per M yen of product shipped※ |

Target | 35.50 | 35.14 | 37.86 | 37.48 | 37.10 |

| Result | 34.85 | 38.25 | 32.99 | 27.21 | - |

Objective Scope:Sanwa Shutter Corporation (Factories)

※Waste Emissions intensity…Waste Emissions (kg)/Shipment Value (M yen)

| FY2019 | FY2020 (Base Year) |

FY2021 | FY2022 | FY2023 (Target) |

||

|---|---|---|---|---|---|---|

| Industrial Waste Emissions (t) | 4,576 | 4,798 | 4,426 | 3,868 | - | |

| Industrial Waste Emissions intensity per M yen of sales※ |

Target | 23.23 | 22.99 | 23.82 | 23.58 | 23.34 |

| Result | 21.75 | 24.06 | 21.48 | 17.34 | - |

Objective Scope:Sanwa Shutter Corporation (Offices)

※Industrial Waste Emissions intensity…Industrial Waste Emissions (kg)/Sales (M yen)

Initiatives to Reduce Waste (North America)

At Overhead Door Corporation (ODC) plants, metal scraps and other waste are sorted by part and type, then recycled. This initiative also contributes to the effective use of resources and waste reduction.

We ourselves developed and installed a system for removing zinc from powder coating wastewater at Lewistown plant of ODC, rolling shutter manufacturing. This system makes possible the efficient removal of zinc to stricter standards than those mandated by the U.S. Environmental Protection Agency. It is also easy to operate.

At the Conneaut plant at ODC, where resin panels and parts are made, we recycle waste oil. We have collected 71 gallons (roughly 269 liters) of waste oil as of December 2022.

-

Metal scraps -

Cardboards -

Zinc removal system at the Lewistown plant

At all our business locations, we install recycling bins in offices and conference rooms, and we recycle toner cartridges, as part of our efforts to reduce waste. In addition, the Sales center in San Francisco is producing wood chips from sawdust, and using them for flower beds, etc.

Collaboration with external organizations to reduce waste and use of resources

At Venix Co., Ltd., a manufacturer of partitions, waste wood (sawdust) produced during the fabrication of toilet booths was previously disposed of, but now it is sold as a valuable resource to disposal businesses. In this way, we are contributing to a reduction of waste (monthly average volume: 11.7 metric tons). Most of the sawdust is eventually reused as bedding in cow barns.

Initiatives to Reduce Waste (Europe)

The NF Group’s Riexinger plant, a door manufacturing plant in Germany, has introduced a new powder coating line. Powder coating provides a high-strength, high-quality coating and enables the paint to be recycled, so it results in conservation of resources while reducing paint loss.

Initiatives to Reduce Waste (Asia)

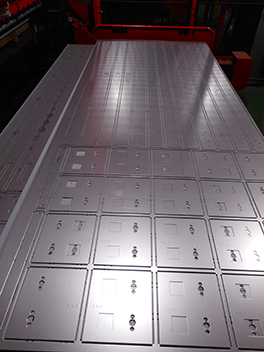

An-Ho Metal Industrial Hsinchu Plant has increased yields 4.4% by purchasing steel sheets that match the size of finished door frames and by improving placement efficiency during steel sheet nesting. These moves contributed to the effective use of resources and the reduction of waste.

operation in March 2022

Vina-Sanwa in Vietnam increased the production capacity of its powder coating facilities from March 2022, and is promoting a shift from solvent coating to powder coating, which has les environmental impact.

Because organic solvents are not used, paint can be recovered and reused, reducing paint loss and preventing air and water pollution caused by the generation of volatile organic compounds.

Promotion of Green Purchasing

The Sanwa Group actively conducts environmental management by promoting green purchasing that prioritizes materials with minimal environmental impact.

Promoting 3Rs for Packaging Materials (Japan)

At Sanwa Shutter Corporation, manufacturing and purchasing departments take the lead in visiting plants and suppliers to propose improvements to promote the 3Rs (Reduce, Reuse, Recycle) for packaging materials.

Specifically, we encourage the use of reusable shipping cartons*, the simplification of packaging and reducing the use of wood by reusing wooden pallets.

*Recyclable cartons are used to transport materials, parts and products between suppliers and plants

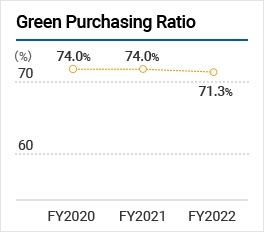

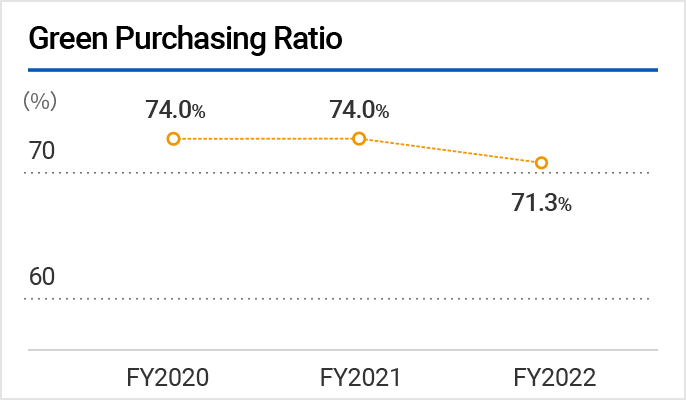

Set Green Purchasing Ratio (Sanwa Shutter Corporation)

Sanwa Shutter Corporation promotes green purchasing to source materials and parts that have a low environmental impact throughout the supply chain.

The company issued “Green Purchasing Guidelines” as a guide for sourcing materials in 2009 and promotes eco-friendly purchasing activities together with our suppliers in an effort to ensure we live in harmony with the global environment.

A green purchasing ratio was set in fiscal 2018, and the company commenced initiatives to boost the ratio by making recommendations and through dialogue with suppliers.

We will continue to visit our suppliers and encourage them to acquire ISO and private sector certifications. We will also provide specific recommendations for actions to take to manage and reduce waste.

Green Purchasing Evaluation Standards

- Status of acquisition of certifications from third-party certification organizations (ISO 14001 etc.)

- Requirements for establishing and operating an environmental management system

- Management of environmentally hazardous substances contained in products

- Environmental impact on business activities

- Environment-related laws and regulations